Managing the Supply Chain: The Shaping Potential of Artificial Intelligence

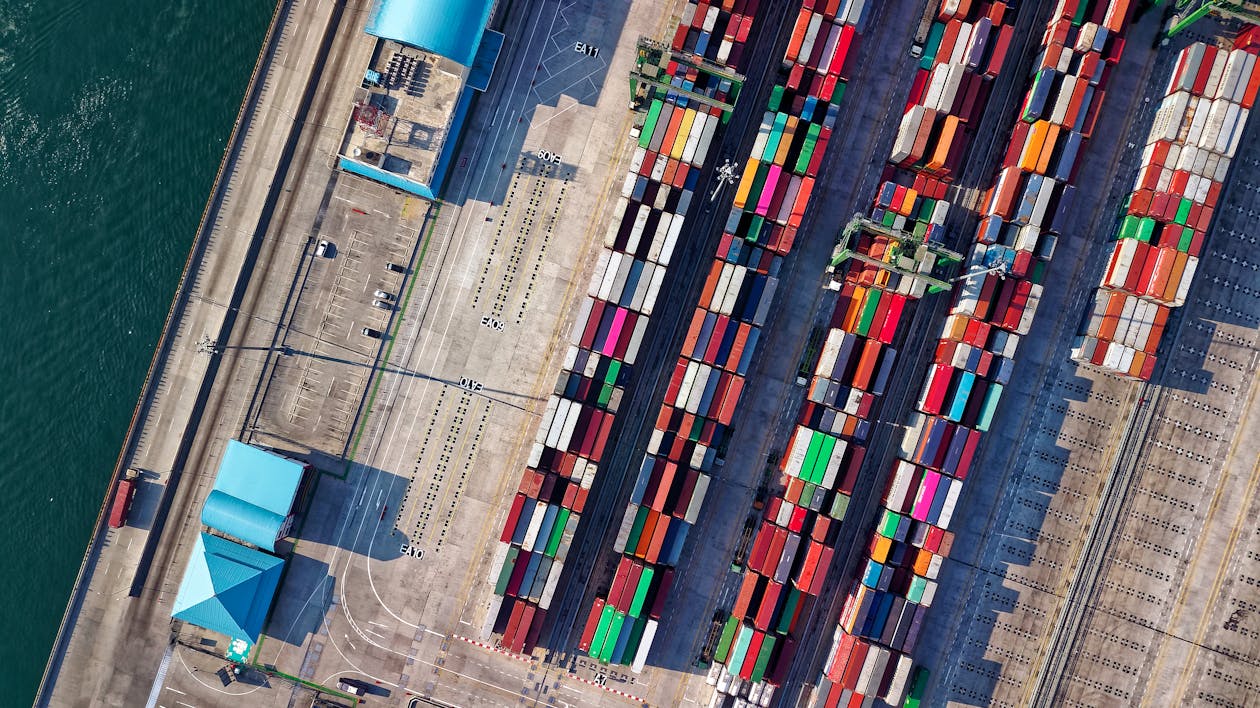

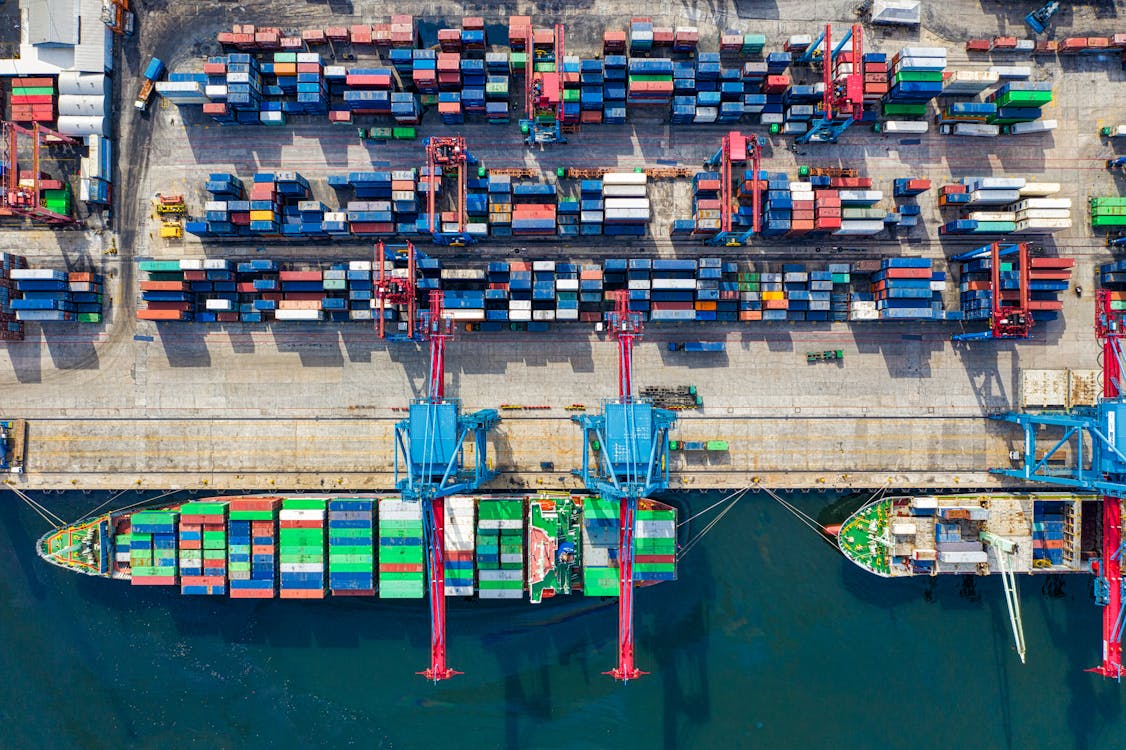

Supply Chain Management (SCM) is a broad spectrum of activities required to plan, control, and execute the processes in the best possible way, from the sourcing of a product or the procurement of materials for its manufacture to its delivery to the final customer, including manufacturing processes as the case may be.

Supply Chain Management (SCM) is a large and complex undertaking that includes everyone from suppliers to manufacturers. Therefore, supply chain management, which must be practical or effective according to the company’s strategy, also requires cooperation and risk management to create harmony and communication among all participants.

Planning in the supply chain brings benefits such as new efficiencies, higher profits, lower costs, and increased collaboration. This management enables companies to manage demand better, keep the right amount of inventory, deal with disruptions, minimize costs and meet customer demand in the most efficient way possible. These Supply Chain Management (SCM) benefits are achieved by choosing effective strategies and appropriate software to manage the increasing complexity of today’s supply chains. Companies use both business strategy and proprietary software in these strategies to gain a competitive advantage.

Supply Chain Management (SCM) has significant implications for the business and the consumer. An adequate supply chain optimization can maximize customer satisfaction by ensuring that the required products are found at the right place and at the right time.

In addition to customer satisfaction, supply chain management provides a tremendous advantage for companies by reducing operating costs. Reducing costs improves the company’s financial position by increasing profit and cash flow.

In addition to all these, another issue that companies attach importance to is the value they add to the environment and society. Although little known by the end consumer, supply chain optimization will reduce fossil fuel consumption and carbon emissions with less product movement. This result has a critical role in the fight against global climate change.

The Role of Artificial Intelligence in Supply Chain Management

Artificial Intelligence (AI) has made visible changes in technologies worldwide. But perhaps the most significant potential of Artificial Intelligence (AI) is its role in the Supply Chain Industry. Artificial Intelligence (AI) has taken the supply chain process from reactive to proactive, creating a more substantial change in how data-driven methods will work in the future. Technology is critical in today’s Supply Chain Management (SCM), and every primary supply chain management process has its software category. However, very little Supply Chain Management (SCM) software uses optimization and simulation techniques while performing the supply chain planning function. Examples of software that do not include these capabilities are TMS, WMS, and ERP systems. The supply chain planning technologies we offer as Digitalis help with optimization and simulation to solve modern challenges, including big data, predictive analytics, IoT, supply chain analytics, robotics, autonomous vehicles, supply chain risk, and sustainability.

Artificial Intelligence (AI) has a dual role in supply chains. The first is automating repetitive tasks and processes in supply chain functions. The second is to introduce new forms of strategic decision–making and collaboration.

The pandemic has forced companies to rethink their supply chains in nearly every industry. This impetus has moved industries from being dependent on other countries to the new goal of developing their capabilities to produce materials. Therefore, the value of downsizing and localizing the supply chain process through Artificial Intelligence (AI) is more evident than ever before.

One of the most common applications of Artificial Intelligence (AI) in this industry is the development of Graphical Processing Units (GPUs) that extend the typical operation of CPUs. With the ever-increasing rate of data creation in the logistics industry, Big Data feeds Artificial Intelligence (AI) enough to reach its highest potential. Intelligent algorithms provide valuable and precise information for companies to obtain approximate prices and times for deliveries, such as details of available trucks to be delivered ahead of time. In addition, Artificial Intelligence (AI) provides advanced contextual intelligence to improve knowledge of reducing inventory and operating costs. This offers faster client communication. Adopting Machine Learning (ML) and Artificial Intelligence (AI) technologies provides more in-depth insights into logistics and warehouse management, Supply Chain Management (SCM), and collaboration.

Technology is also helping the smallest suppliers behind the scenes. For example, sending and receiving invoices uses artificial intelligence to automatically extract data from invoices, verify and match confirmed orders, and resolve issues.